In the world of metalworking, seamless rolled rings stand as a testament to precision engineering and superior strength. These specialized components play a pivotal role in a multitude of industries, from aerospace and automotive to energy and beyond. Let’s delve into the nuances of seamless rolled rings, exploring their manufacturing process and highlighting the prowess of Millennium Rings as one of the leading manufacturers in India.

Seamless rolled rings, a product of precision forging, have earned a prominent place in various industries due to their unique properties and versatility. In this comprehensive exploration, we delve into the wide array of applications where seamless rolled rings play a pivotal role.

Understanding Seamless Rolled Rings:

1. The Forging Process:

Seamless rolled rings are forged through a meticulous process that involves shaping a circular metal preform, often referred to as a “doughnut” or “ring blank,” into the final seamless ring. This process is typically accomplished through the application of heat and controlled pressure, ensuring a consistent and defect-free end product.

2. Material Selection:

The choice of material is crucial in ensuring the performance of seamless rolled rings. Commonly used materials include carbon steel, alloy steel, and stainless steel, each selected based on the specific requirements of the application.

3. Heat Treatment:

Following the forging process, seamless rolled rings undergo heat treatment to optimize their mechanical properties. This step enhances attributes such as hardness, toughness, and overall durability, ensuring the rings meet the highest standards of quality.

Applications Across Industries:

Aerospace Industry

Seamless rolled rings find extensive applications in the aerospace sector, contributing to the production of critical components such as jet engine parts, landing gear, and structural elements. The inherent strength and durability of seamless rolled rings make them an ideal choice for withstanding the rigorous conditions encountered in aviation.

Automotive Sector

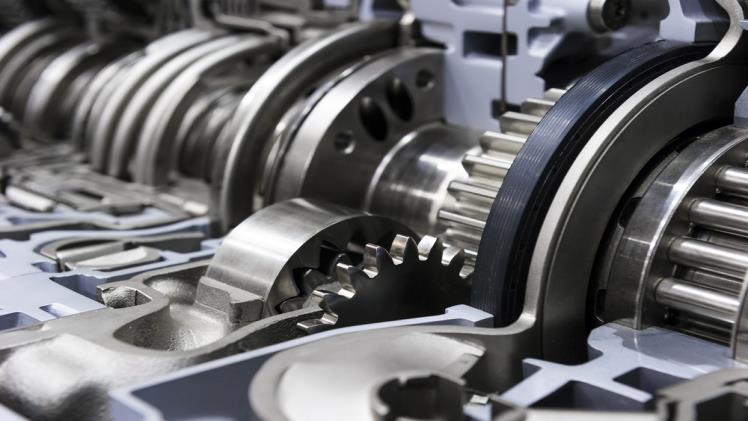

In the automotive industry, seamless rolled rings are utilized for manufacturing key components like bearings, gears, and flanges. Their ability to withstand heavy loads and provide enhanced durability contributes to the reliability and performance of automotive systems.

Energy and Power Generation

Seamless rolled rings play a crucial role in the energy sector, particularly in the production of components for power generation equipment. From turbine discs to generator rings, the high-strength characteristics of seamless rolled rings make them essential in ensuring the efficiency and reliability of power generation systems.

Industrial Machinery

Various industrial machinery, including heavy equipment and machinery used in manufacturing processes, relies on seamless rolled rings for components that demand high strength and resistance to wear. These rings contribute to the overall efficiency and reliability of industrial systems.

Oil and Gas Applications

In the oil and gas industry, seamless rolled rings are employed in the manufacturing of critical components for drilling equipment, valves, and other applications. The ability of seamless rolled rings to withstand extreme conditions, including high pressure and temperature, makes them invaluable in this demanding sector.

Bearings and Gearing Systems

Precision is paramount in bearings and gearing systems, and seamless rolled rings deliver just that. Their reliability and resistance to fatigue make them a preferred choice for manufacturing components that ensure smooth operation and longevity in various machinery and equipment.

Defense and Military Applications

Seamless rolled rings play a vital role in the defense sector, contributing to the manufacturing of components for military vehicles, aircraft, and weaponry. The strength and durability of these rings meet stringent quality standards, making them well-suited for defense applications.

Construction and Infrastructure

Certain construction applications benefit from the use of seamless rolled rings, particularly in components for cranes and other heavy equipment. The strength and reliability of these rings contribute to the safety and stability of construction equipment and infrastructure.

Millennium Rings: Leading the Way in Seamless Rolled Ring Manufacturing:

1. Commitment to Quality:

Millennium Rings, as a leading manufacturer in India, stands out for its unwavering commitment to quality. Their seamless rolled rings undergo rigorous inspection and testing to ensure they meet or exceed industry standards.

2. Technological Excellence:

Leveraging state-of-the-art technology and advanced manufacturing processes, Millennium Rings achieves precision and consistency in the production of seamless rolled rings. Their technological prowess positions them at the forefront of the industry.

3. Customization for Diverse Needs:

Understanding the diverse needs of different industries, Millennium Rings offers customization options for seamless rolled rings. This ensures that each component is tailored to specific requirements, demonstrating a flexibility that sets them apart.

4. Sustainability and Efficiency:

Millennium Rings emphasizes sustainable manufacturing practices, minimizing material waste and optimizing energy efficiency. This commitment aligns with global efforts toward environmentally conscious production.

Conclusion:

Seamless rolled rings represent a marriage of strength, precision, and reliability in the world of metal components. As one of the leading manufacturers in India, Millennium Rings not only meets the stringent demands of various industries but surpasses them with a dedication to excellence. Their seamless rolled rings embody the essence of quality craftsmanship, making them a trusted choice for those seeking components that withstand the test of time. As technology advances, the versatility and strength of seamless rolled rings will likely continue to shape the landscape of various industries, contributing to innovation and excellence.