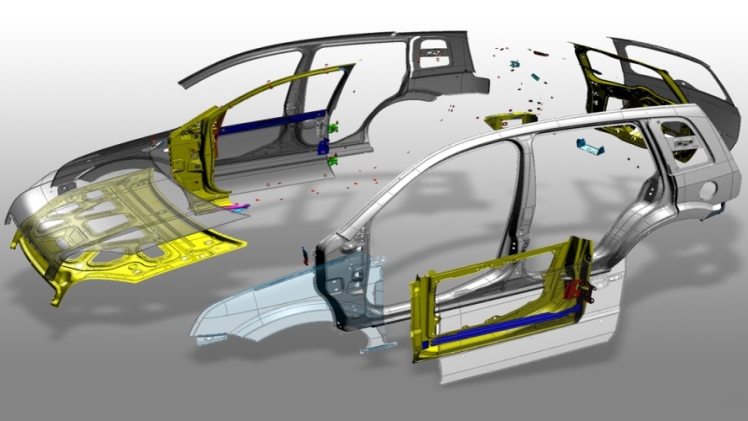

BIW, or body in white, refers to automobile manufacturing where the body component of a car has been joined together using one or a combination of different techniques like welding, bonding clinching, laser brazing, etc. BIW is termed before painting and before the motor or trim has been assembled in the frame structure, as per the experts offering the best Biw Fixture Design Course In Delhi.

A fixture is generally a device holding the workpiece to be processed using the principle of 321. The fixtures are designed to hold different parts during the welding under this fixture. It is vital to hold the parts at the proper location so that there is no dissertation to maintain the part at its required position without damaging it. Placement of clamping would be done at the welding area.

Different types of BIW fixture designs

When you join the best Biw Fixture Design Course In Hyderabad, you can learn about the different fixtures.

Production fixtures

These fixtures are mainly used for mass production. It requires optimum consistency through the operation to maintain the geometry of the part so that the material used is thoroughly tested. The fixture needs some maintenance after the operations are completed. The time required for assembly and disassembly must be as slow as possible so that you can save time.

Production operation fixture

The fixtures are designed as prototype fixtures to check the feasibility of the initial production batch. The fixtures would be the best fixture with sets of benchmarks and criteria, which help people rectify the errors they could get from the different manual operations involved. It requires a lot of time and cost also. You need to maintain the cost of the car as low as possible, so you directly go to the production fixture by considering the standards checklist to maintain error-free production.

Checking fixtures

These fixtures are used to check for the purpose. No operations, including Hemming or glueing, would be carried out without these fixtures. The gauges are used in the fixtures to get the perfect dimension and tolerance part, and the information is compared to the design dimensions to check whether the part is okay. The geometry of the welded part would also be checked in the fixture to ensure that the part maintains the required elements.

The basic terminologies used in the fixtures

Principal locating point

These are the points used to accurately locate the part to maintain the geometry of that assembly. There are several holes on the panels, which are not accurate for guru stamping operation.

Risers

Risers of different types, including l-type racer square tube risers. It is the manufacturing part which gives high to the assemblies.

Blade

Blades are plates mounted on the riser. Other parts, including cylinder arms, are then mounted on the blade.Hardware

The hardware includes hex nuts, spring washers, and others.

CMM

CMM means the coordinate measuring machine, a device that measures the geometry of physical objects by just sensing discrete points on the object’s surface featuring a probe. It generates a report by comparing the information using the CAD file information.

Conclusion:

Hence in the current times, BIW fixture design courses are very much in demand today, and with the help of the right courses, you can ace them.